Food industry

Semolina

Rigorously selected durum wheat

Producing quality semolina requires making an optimal blend of different varieties of durum wheat.

The elimination of batches of durum wheat with damaged or dark grains is an important step in making good semolina.

The quality of the proteins is also crucial for the firmness of the final products.

A satisfactory ‘yellow’ index also ensures an appetising amber-yellow colour for pasta and semolina.

Last but not least, the analysis of each production run before delivery to the end customer guarantees compliance with established specifications and optimum quality for each product.

-

Tailor-made semolina

for a variety of uses.

-

IFS Food certification

Thanks to its state-of-the-art facilities, Moulins de Kleinbettingen guarantees optimum food safety throughout the entire process. It has been IFS food certified at the highest level since 2010.

-

Adapted packaging

to suit your needs, from 1 kg bags to bulks.

Types of semolina

There are several types of semolina:

- Extra-fine semolina is used to make bread, pancakes and other fluid preparations.

- Fine semolina is used to make pasta and cakes.

- Coarse and medium semolina are ideal for Middle Eastern pastries.

Find our complete range in our catalogue.

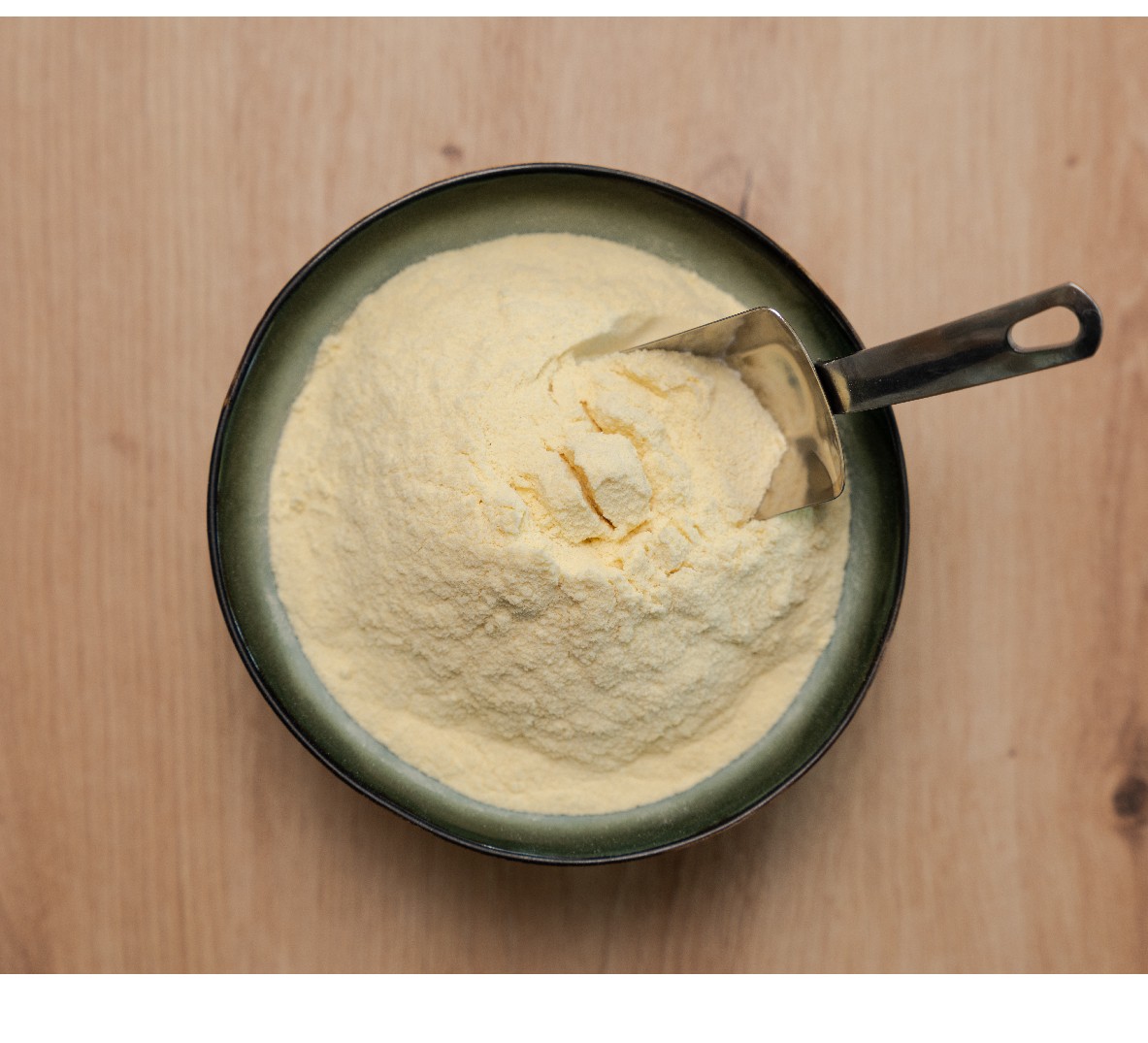

From durum wheat to semolina

Semolina is the result of milling the grain of durum wheat. It is used in the production of pasta and couscous.

All semolina contains mineral substances derived from the bran. Each semolina is graded by its ash content, representing the amount of minerals it contains after burning.

- The lower the ash content, the more refined the semolina.

- The higher the ash content, the more the semolina is considered ‘whole’.

Semolina

Semolina is obtained from coarsely milling moistened cereal grains (durum wheat) followed by drying and sifting.

It is the intermediate product between the grain and the flour.

Different qualities of durum wheat semolina impact the final result of the pasta. The quality is determined by assessing various factors:

- Ash content: fineness of the semolina

- Black spots: presence of impurities in the semolina

- Fat content of the raw ingredient

- Visual appearance of the semolina: colour and particle size

- and others